12

2024

-

11

MiP Technology Empowered: Sinyopto Optoelectronics Ushers in a New Era for the Micro LED Industry

November 6–8, The 5th China International Mini/Micro LED Industry Chain Innovation and Development Summit Forum Held at the Shenzhen International Convention and Exhibition Center, hundreds of industry professionals gathered to engage in in-depth discussions and exchanges on various topics, including MLED technology development, mass production progress, and product market strategies, all aimed at accelerating the industrialization of Mini/Micro-LED technologies.

Zhao Qiang, Deputy Director of the R&D Department at Sinyopto Optoelectronics, delivered a speech at the forum. "Industrialization Advantages and Progress of Micro LED Display Panels Based on MiP" The speech highlighted the advantages of SinyoptoMiP technology and its critical role in the industrialization process.

Micro LED: The Rise and Challenges of the Industry's First Year

Mini/Micro LED technology continues to push boundaries, and Micro LED is now poised for a breakthrough. Industry's First Year 。

Technological breakthroughs Especially in key areas such as high pixel density (PPI), transparency, and curved-surface designs, Micro LED products have already achieved industry-leading performance. With their exceptional picture quality, brightness, and longevity, Micro LED technology has gained traction across multiple sectors, including AR glasses, televisions, and automotive displays. Widely applied , and has won the market's favor. National policy support It has laid a solid foundation for the development of Micro LED technology. Meanwhile, cost optimization, technological maturity, and Industrial chain Collaborative innovation is propelling the Micro LED market into a critical phase of rapid growth and industrialization.

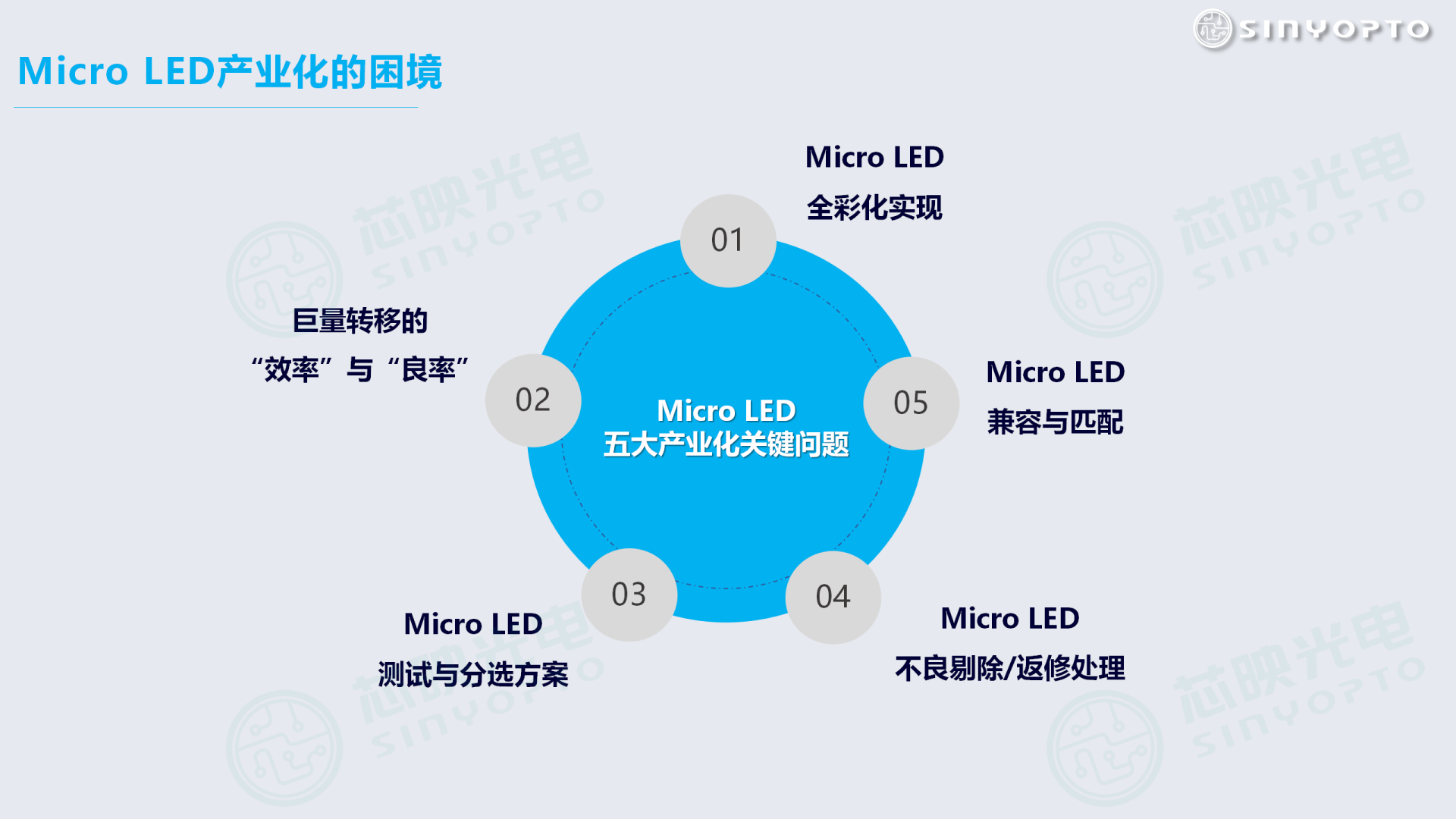

-Micro LED Industry Challenges-

However, the path to industrialization of Micro LED It hasn’t been smooth sailing. The industry has yet to reach a consensus on its definition and standards, and issues such as low process yields and high rework costs have become bottlenecks hindering large-scale production. While companies strive to achieve performance advantages like high brightness, superior transparency, and enhanced reliability, they must also effectively address the challenge of balancing cost control with economic profitability.

MiP: Breaking Through the Industrialization Bottleneck of Micro LED

True Micro LED — MiP:

MiP technology, or Micro LED in Package, utilizes True Micro-level chips with substrate removal and mass transfer technology , MiP not only boosted productivity but also significantly reduced costs.

Take Sinyopto Optoelectronics' MiP0202 product as an example, leveraging 34 × 58 µm Its ultra-small chip size enables wide compatibility with P0.3 to P0.9, and Substrate was stripped. Through Massive Transfer The MiP technology significantly boosts production efficiency, effectively reduces costs, and enhances flexibility in applications such as wearable devices and transparent displays.

-

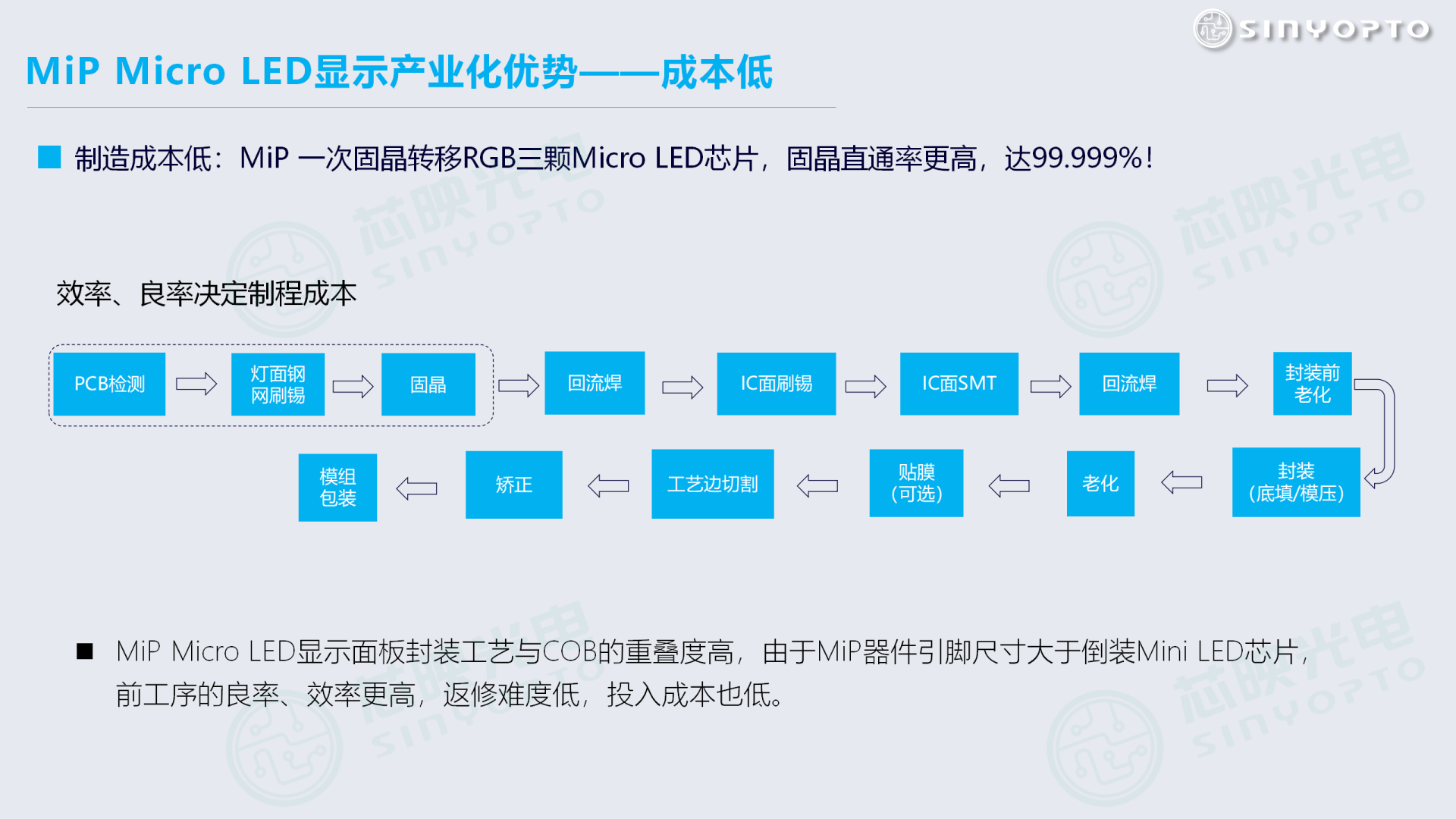

Simplified manufacturing process

Through Fan-out Technology By re-routing and fan-out-pinning the Micro LED chip substrate, larger pads are achieved, simplifying both testing and mounting processes. This technology also helps reduce manufacturing investment costs.

-

Improved display quality

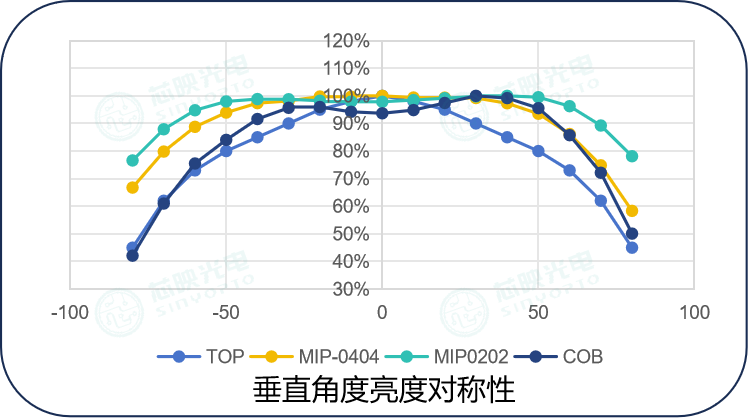

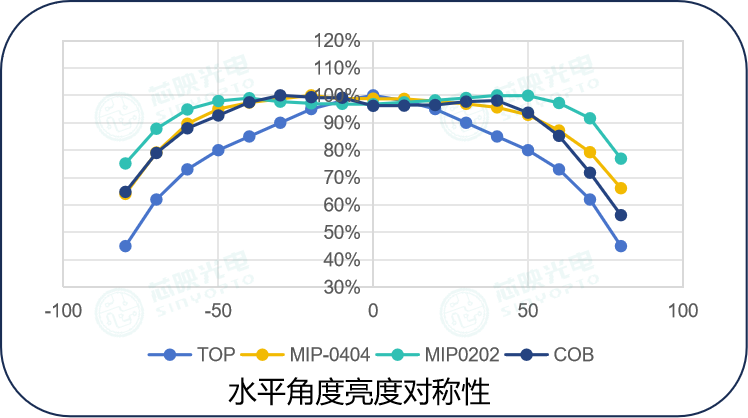

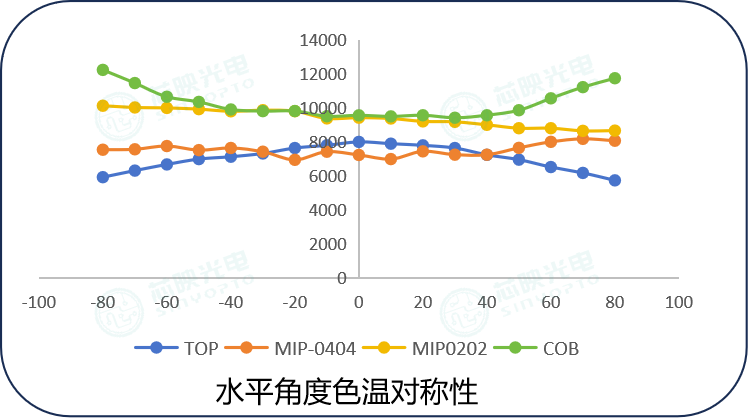

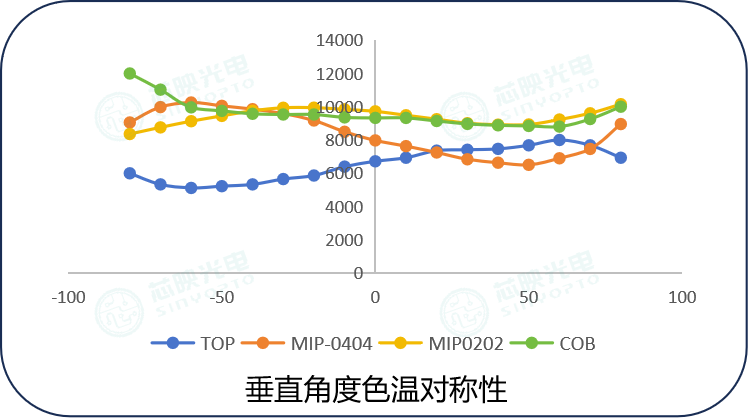

-MiP Micro LED boasts excellent angular brightness symmetry-

-MiP Micro LED exhibits minimal color temperature variation across different angles-

MiP employs pixel-level full testing and sorting technology to ensure color consistency across every pixel, delivering exceptional display uniformity that prevents any visible inconsistencies when viewing large screens. Modular Color Difference 。

Additionally, thanks to the true Micro LED chip's substrate-free design, the chips exhibit exceptional flatness in arrangement, resulting in minimal color temperature fluctuations—whether viewed at horizontal or vertical angles. Symmetry between Brightness and Color Temperature Both are excellent.

-

Cost-Benefit Optimization

MiP achieves a single die bonding through-rate as high as 99.999% , effectively reducing manufacturing costs. Moreover, the smaller size of Micro LED chips allows for greater potential in lowering MiP device costs, providing strong support for large-scale industrialization.

-

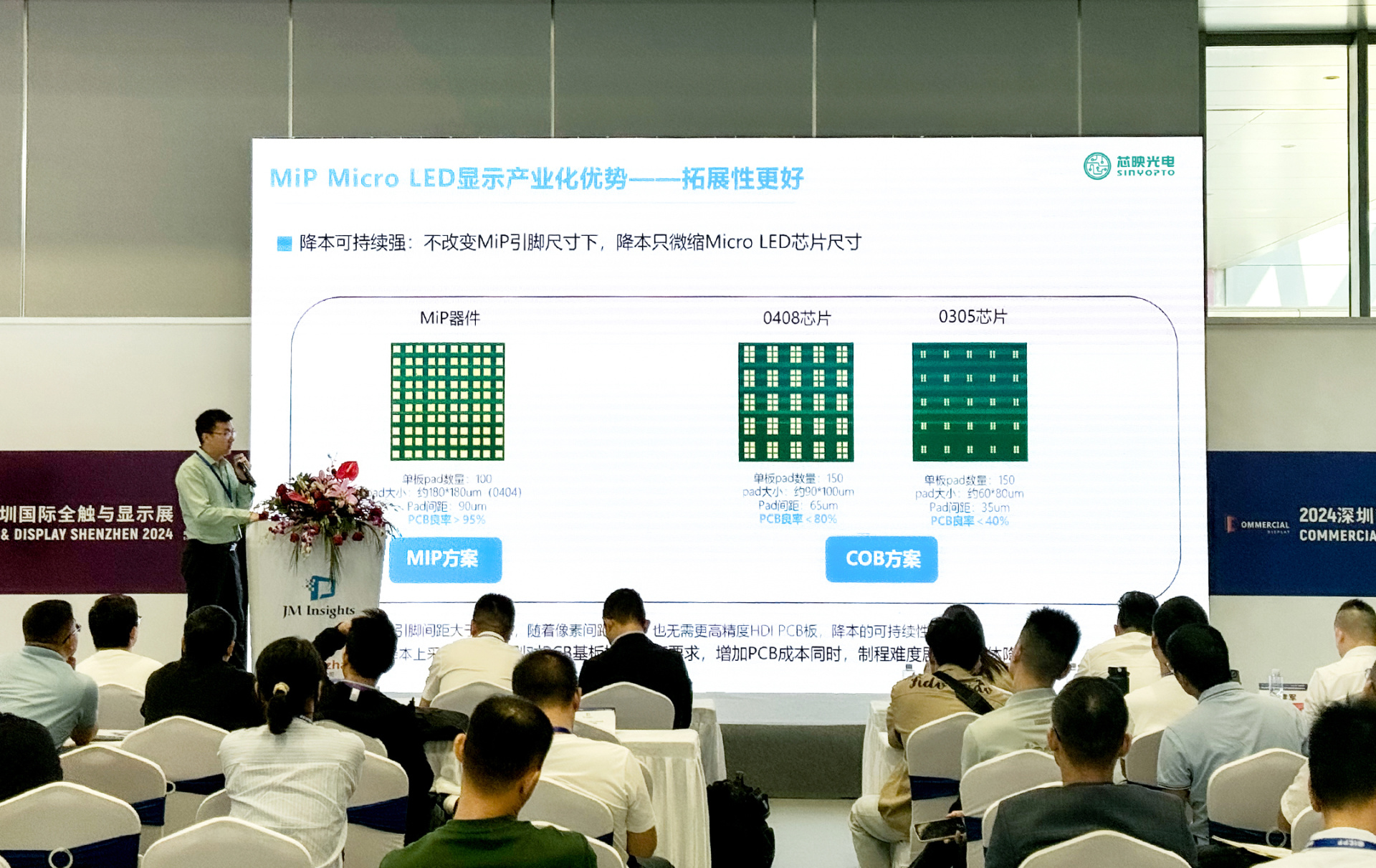

Strong compatibility and adaptability

MiP features a wide pin pitch, making it suitable for driving panels with varying pixel pitches and different material types. It can… Suitable for a variety of application scenarios The demand for miniaturized Micro LED chips is growing, with a significant downward trend in chip size.

Sinyopto Optoelectronics: Continuously Innovating and Optimizing MiP Technology

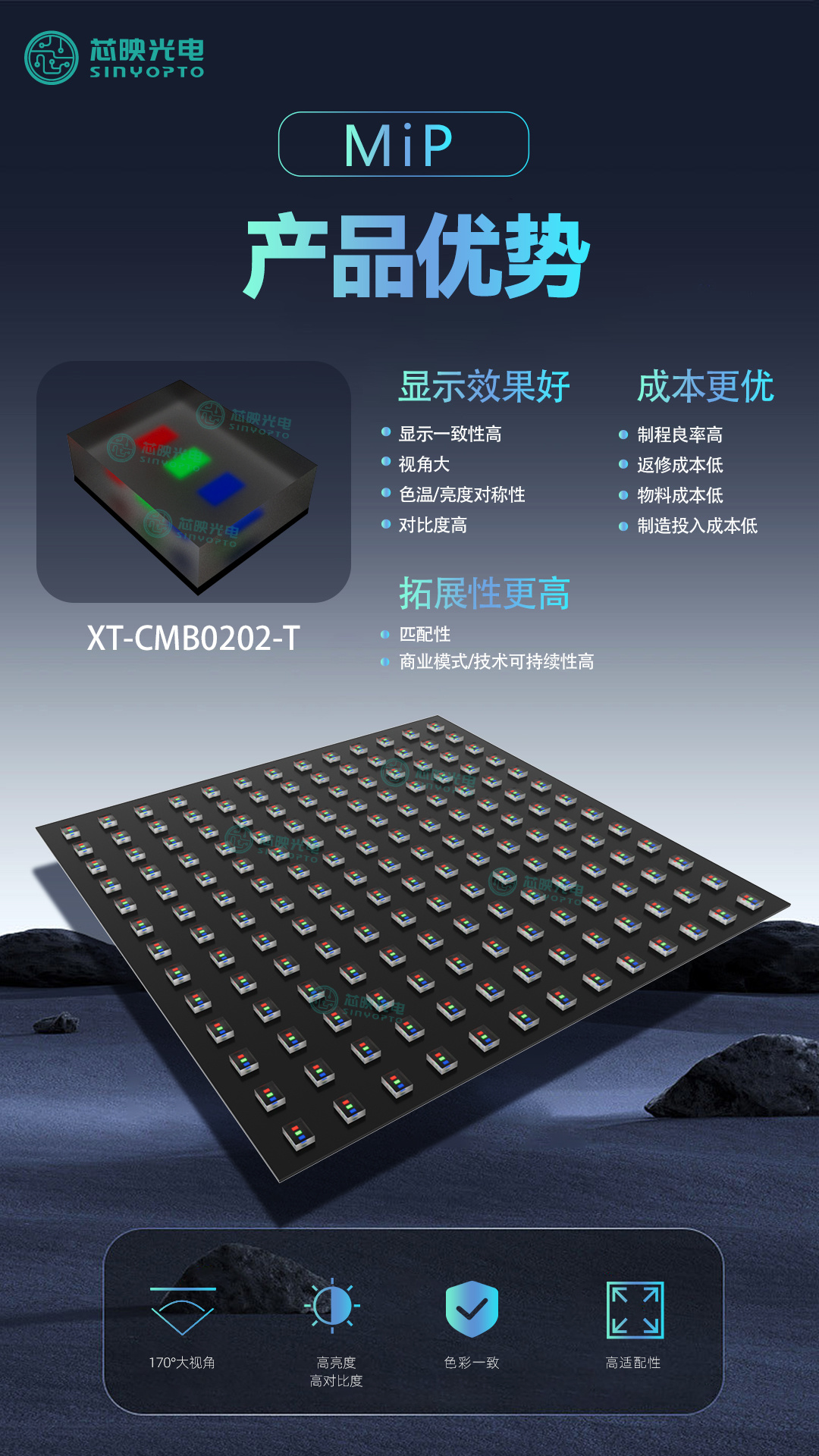

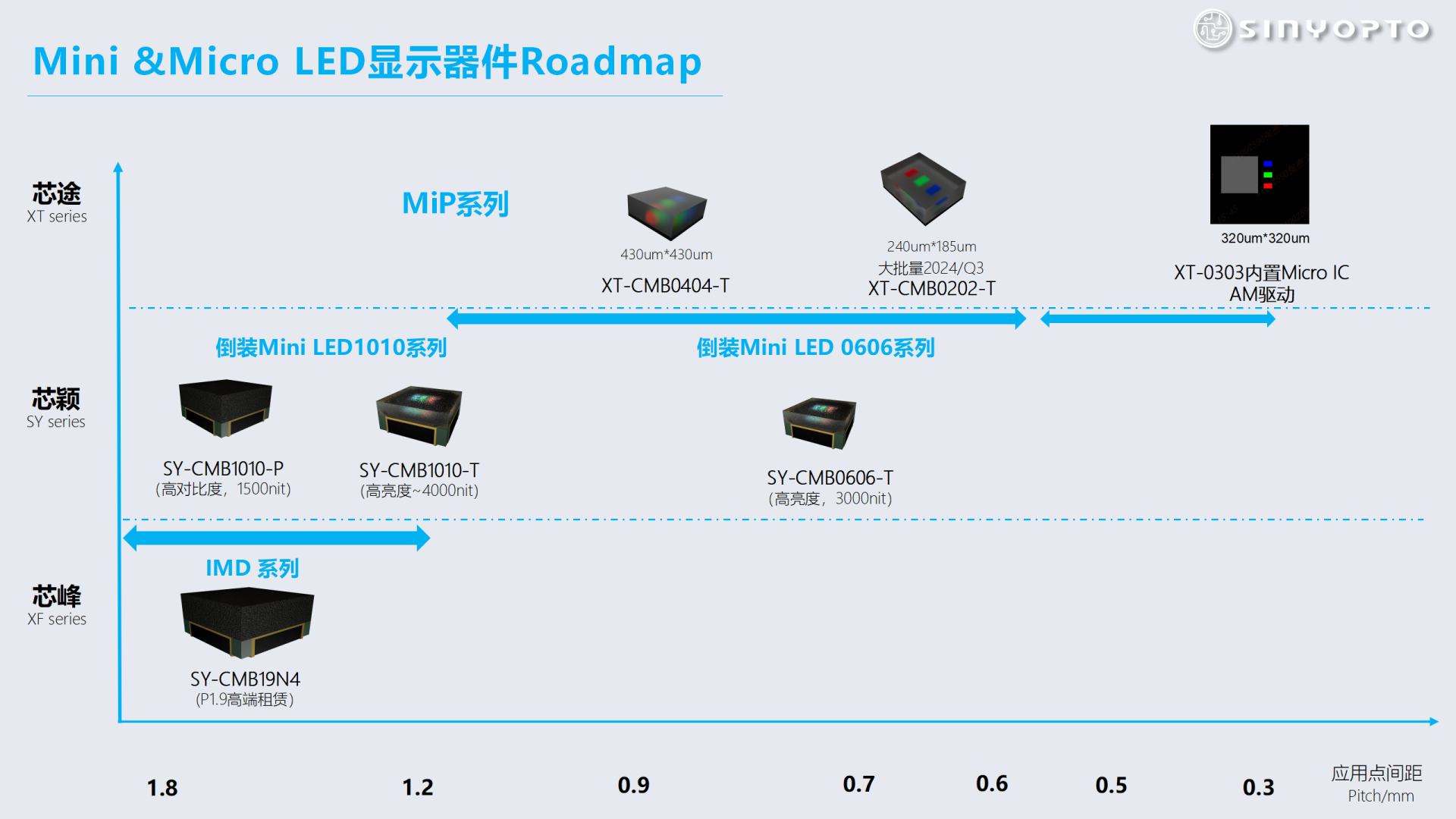

Leveraging its deep expertise and ongoing innovation in the Mini/Micro LED field, Sinyopto Optoelectronics continuously introduces highly competitive products. XT-CMB0202-T With its outstanding display performance, exceptional black levels, sleek and lightweight design, and strong compatibility, it has garnered widespread attention in the market.

And the upcoming A-MiP The product further integrates AM IC and RGB Micro LED into a single LED chip.

Building on the performance enhancements of the first-generation MiP, this new version features a smaller chip and integrates both lamp-driven and active-drive technologies. This innovative approach resolves the limitations of traditional passive driving, eliminating issues like the "caterpillar effect," low-gray coupling, and flickering—resulting in improved viewing comfort and delivering superior display quality.

Looking ahead, we can confidently expect Sinyopto Optoelectronics to continue embracing its spirit of innovation, relentlessly refining MiP technology while further driving the widespread adoption of Micro LED across more industries. This will ultimately lead to a seamless integration of cutting-edge technology and market demand, solidifying the company as a powerful catalyst for the growth of the Mini/Micro-LED industry.