Towards Smart Factories

Illuminating a New Era of Intelligent Manufacturing

Sinyopto places intelligent manufacturing at the core, building a fully digitalized ecosystem spanning from R&D and design to production and delivery.

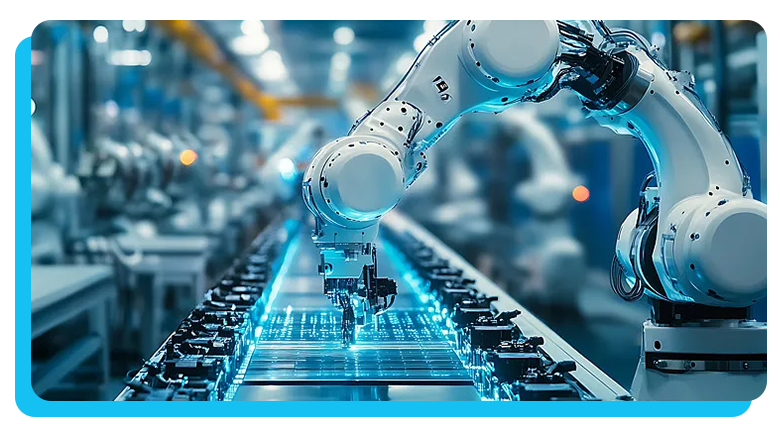

Leveraging the Industry 4.0 framework, the company establishes dedicated automated manufacturing units, achieving real-time device interconnectivity,

data acquisition, and intelligent analysis, ensuring high product quality and stable production.

Actively supporting the national “Digital China” strategy, Sinyopto accelerates the upgrade of next-generation smart factories.

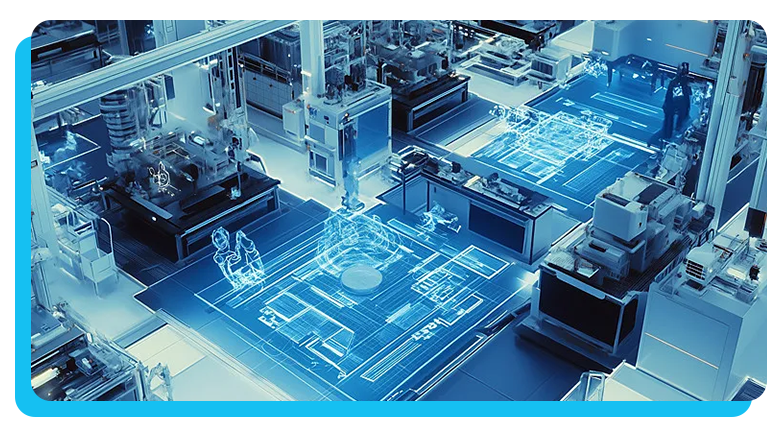

Through the “Four-Dimensional Intelligent Manufacturing System” (Intelligent Manufacturing × Digital Operations × AI Decision-Making × Cloud Collaboration),

the company advances toward exemplary, leading-level digital twin demonstration factories, delivering more efficient and reliable solutions to the global display industry.

Intelligent Manufacturing

Digitalized Management

Intelligent Decision-Making

Collaborative Ecosystem Networking

Panoramic Intelligent Manufacturing Strategy

Foundation: Intelligent Production Lines

✥In 2024, full-scale integration of automatic die-bonding and wire-bonding equipment began, with factory-wide device interconnectivity, targeting 90% automation coverage in key processes.

✥Implemented MES production execution system, digitizing process parameters, enabling visualized quality traceability and transparent process management.

Forward-Looking: Digital Twin Technology

✥Partnered with Hexagon, Pangu, and others to develop an industrial internet platform, planning for equipment interconnectivity and energy efficiency monitoring systems.

✥Developed AI optical inspection models, exploring intelligent control for high-quality LED production.

Building a Green Manufacturing Ecosystem

✥Designed an integrated photovoltaic energy storage solution, aiming to reduce energy consumption per LED by 30% within three years.

✥Collaborated with upstream chip manufacturers to develop recyclable packaging materials, targeting material recovery rates over 85%.

Innovation-Driven Industry Co-Win

Sinyopto understands that intelligent manufacturing is not a technology arms race, but a systematic approach to creating value for customers. Through a three-year phased implementation plan, the company aims to gradually achieve:

Flexible manufacturing with shortened order delivery cycles

Million-level LED binning efficiency through an intelligent sorting system

20%

Order delivery with flexible manufacturing

capabilities

Shortened cycle

50%

Million-level LED beads in an intelligent

sorting system

Improved Bin Efficiency

Compatible Processes

Modular production lines compatible

with COB and MiP processes

Open-Style Intelligent Manufacturing Innovation Alliance

Partnering with equipment manufacturers, integrators,

and research institutions to ensure that every LED chip embodies a measurable commitment to quality and ecological value.